Increase your competitiveness

With digital processes from c-Com

Digital solutions for your success

c-Com provides software and services to digitize your tooling and machining processes to boost your productivity.

Introduction

Lately many companies in the metal cutting industry ask themselves how to reduce indirect cost to manage c-parts such as cutting tools. The more valuable tools are, the more transparency is needed to reduce unnecessary safety stock and thus decrease fixed capital. Lowering direct cost such as tool consumption and increasing productivity by indicating tool changes ahead of time and identifying production issues and their causes digitally helps to increase your success. c-Com supports you with these challenges in order to keep your business competitive.

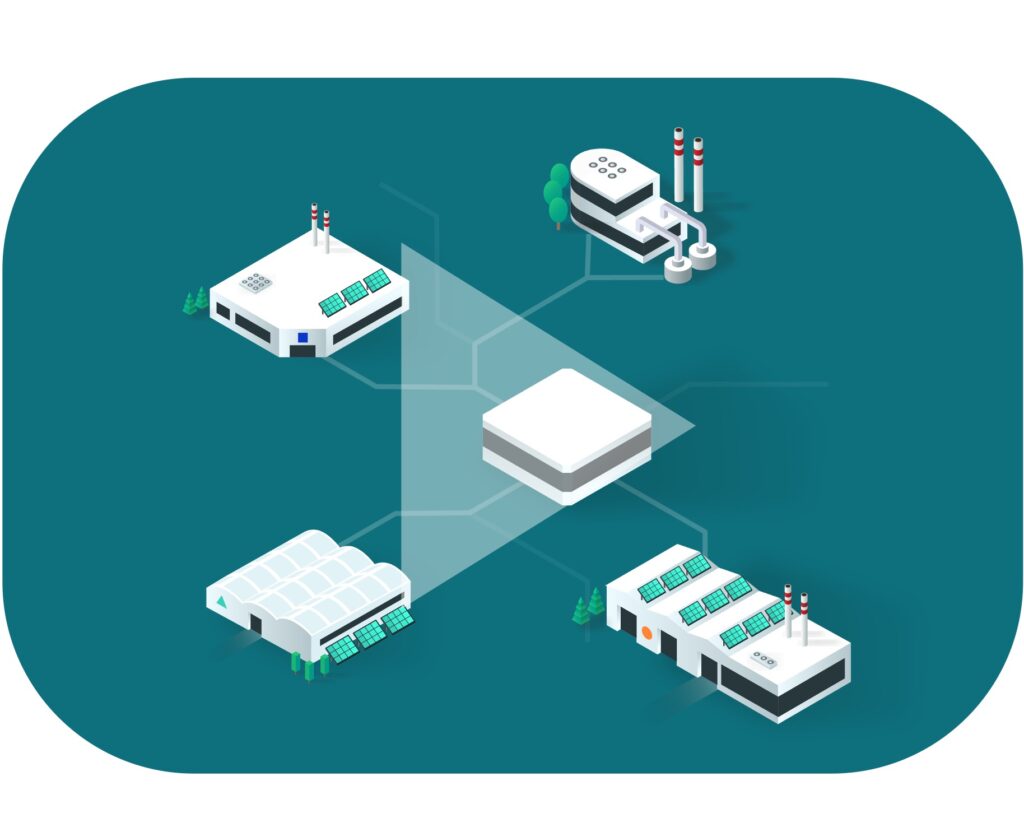

Solution Overview

With the focus on the application of tools our Digital Tool Management (DTM) solution is the basis of our software products. Often this solution is extended with a Life Cycle Management (LCM) providing a digital twin of individually marked tools. Finally we offer to increase your productivity with our Machining Analytics Solution (MAS).

Digital Tool Management

Transparency on inventory

Transparency on application

Transparency on performance

Common data basis

Collaborative feature

Life Cycle Management

High transparency on tools

Reduced efforts for management

Optimization of tool performance

Regrinding and coating process

Optimized planning

Machining Analytics Solutions

Quality optimization

Tool application recommendations

Automated tool wear inspection

Cost reduction

Increased OEE

Feature Availability

Feature | DTM Digital Tool Management | LCM Life Cycle Management | MAS Machining Analytics Solutions |

Cutting Tools

| |||

Application data

| |||

Serialized Tools

| |||

Inventories and storage locations

| |||

Disposition proposals

| Order Cockpit Add-on | ||

Cost Reporting

| |||

Tool Performance Reporting

| |||

Tool Tracing

| |||

Material Batch Tracing

| |||

Logistic Client Web application for handling logisitcs processes

| |||

Tool Assistant App Windows, Mac, Android and iOS/iPad OS app to handle tools and process material batches | |||

Analytics Dashboard This module requires near real-time connectivity to your systems and machines | |||

Live-View on Tooling In addition to ARTIS hardware, we offer the following software features:

| ARTIS Add-on | ARTIS Add-on | ARTIS Add-on |

Connectivity

Please note that despite the many possibilites, it is necessary to check the interfaces of c-Com to your devices in advance | Add-on | Add-on | |

Tool Manager App iPhone/iPad App for tool and workpiece master data:

|

Cutting Tools

Naming, numbering; Bill of material; Technical data; Documents, e.g. drawing; Product groups; Classification; Search

Digital Tool Management ✔

Lifecycle Management ✔

Machining Analytics Solutions ✔

Application data

Workpieces with technical data, documents and classifications; Tool cutting data with multiple steps and components, history of data changes; Production plan and actuals

Digital Tool Management ✔

Lifecycle Management ✔

Machining Analytics Solutions ✔

Serialized Tools

Serial number; Serialized bill of materials; Technical data (e.g. length, refurbishment count); Movement history (where, when, state)

Digital Tool Management ✖

Lifecycle Management ✔

Machining Analytics Solutions ✖

Inventory

Inventory levels for storage hierarchies and states; Typed storage locations for different pro-duct group such as assemblies, durables and components; Inventory lists

Digital Tool Management ✔

Lifecycle Management ✔

Machining Analytics Solutions ✖

Disposition proposals

Static limits (min, max, reorder point); Dynamic limits (e.g. time-based); Inventory development and forecast; Active orders and status; Connectivity with ERP and purchasing systems

Digital Tool Management Order Cockpit Add-on

Lifecycle Management ✖

Machining Analytics Solutions ✖

Cost Reporting

Cost per Part/Workpiece; Cost Drivers per Cost Center; Support for cost center hierarchy; Support for inventory hierchary

Digital Tool Management ✔

Lifecycle Management ✖

Machining Analytics Solutions ✖

Tool Performance Reporting

Tool life reports; Change reasons; Assemblies

Digital Tool Management ✔

Lifecycle Management ✔

Machining Analytics Solutions ✔

Tool Tracing

Circulation inventory with location and state based overview

Digital Tool Management ✖

Lifecycle Management ✔

Machining Analytics Solutions ✖

Material Batch Tracing

Material batches (e.g. regrinding box); Receipts for the batch, e.g. delivery note, order; Overview of orders and inventories outside of premises; Show open/closed orders for an article

Digital Tool Management ✖

Lifecycle Management ✔

Machining Analytics Solutions ✖

Web application for transactions within the logistic process

Goods receipt, goods issue; Tool inspection; Coating orders and processing; Create and transmit measurement proto-cols

Digital Tool Management ✖

Lifecycle Management ✔

Machining Analytics Solutions ✖

Tool Assistant App

Windows, Mac, Android and iOS/iPad OS app to han-dle tools and process material batches

Digital Tool Management ✔

Lifecycle Management ✔

Machining Analytics Solutions ✖

Analytics Dashboard

This module requires connecting machines and us-ing c-Com for tool management

Digital Tool Management ✖

Lifecycle Management ✖

Machining Analytics Solutions ✔

Live-View on Tooling

In addition to ARTIS hardware, we offer the follo-wing software features:

Tool state list (per location, per machine); Upcoming tool changes; Machine state monitoring with alarms

Digital Tool Management ✖

Lifecycle Management ✖

Machining Analytics Solutions ARTIS Add-on

Connectivity

Connection to (CNC) machine (with partners); Connectivity with presetting device (with partners); Connection to dispensing units and tool storage devices; Connect to software systems like ERP systems; Connect to suppliers, e.g. to tool manufac-turers and refurbishment partners

Please note that despite c-Coms many connectivity options we have to individually assess the interface options.

Digital Tool Management Add-on

Lifecycle Management Add-on

Machining Analytics Solutions ✔

Tool Manager App

iPhone/iPad App for tool and workpiece master data:

Tools with application data like cutting parameters; Machines and alarms; Upcoming tool changes and tool overview on machine

Digital Tool Management ✔

Lifecycle Management ✔

Machining Analytics Solutions ✔